2011 Chicago Regional Bridge Building Specifications

These rules have been developed by the Chicago Regional Bridge Building

Committee for the Thirty Sixth Chicago Regional Bridge Building

Contest to be held on Monday, February 28, 2011 at Illinois

Institute of Technology, Chicago IL 60616, USA. If you have a question

about these rules, FIRST take a look at the list of Frequently Asked Questions (FAQ) to see

if the answer is already there. If you have read the FAQ, and still have

a question about the contest rules, then you may contact the Chief

Judge, George Krupa at gekrupa@aol.com. For questions on any

contest topic EXCEPT the rules please contact Prof. John Kallend at

kallend@iit.edu.

The object of this contest is to see who can design, construct and test

the most efficient bridge within these specifications. Model

bridges are intended to be simplified versions of real-world bridges,

which are designed to accept a load in any position and permit the load to

travel across the entire bridge.

1. Materials

-

The bridge must be constructed only from 3/32 inch square

cross-section basswood and any commonly available adhesive.

-

The basswood may be notched, cut, sanded or laminated in any manner.

-

No other materials may be used. The bridge may not be stained,

painted or coated in any fashion with any foreign substance.

2. Construction

-

The bridge mass shall be no greater than 25.00 grams.

-

The bridge (see Figure 1) must span a gap (S) of 300. mm,

be no longer (L) than 400. mm, be no taller (H)

than 150. mm above the support surfaces, and have a width

(W) no greater than 80. mm.

-

The bridge must be constructed to provide a horizontal support for the

loading plate and at each of the three possible loading positions.

These three positions (see 3c). The bridge structure must

allow the loading rod (see 3c) to be mounted from below.

-

The bridge must be constructed to allow a 48 mm diameter,

400. mm long pipe (1.5 inch schedule 40 PVC pipe) to be passed

horizontally across the bridge with the pipe's lower surface on the

loading plane (P) between 80. and 100. mm above the base

of the bridge. This pipe must touch all 3 loading locations

simultaneously (see 3c).

-

The bridge structure may not project below the support surfaces (see

Figure 1).

3. Loading

-

Competition loading will stop at 50. kg, loading will continue until

bridge failure (see 4d).

-

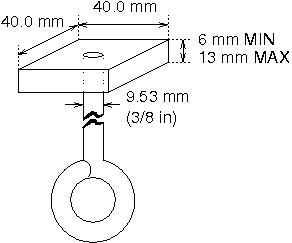

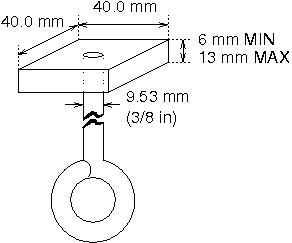

The load will be applied by means of a 40. mm square plate that

is at least 6 mm but less than 13 mm thick. A 9.53 mm

(3/8 inch) diameter eyebolt is attached from below to the center

of the plate (see Figure 2). The plate will be horizontal and will

not pivot on the eyebolt. Masses will be supported on a vertical

loading rod suspended from the eyebolt. The minimum initial load will

be 2. kg.

-

The load will be applied with the center of the plate at one of three

(3) possible locations on the longitudinal axis of the bridge: the

center and 30. mm to the left and right of the center (see Figure

1). The three loading locations must lie in the same horizontal plane.

This loading plane must lie a distance (P) between

80. mm and 100. mm above the base of the bridge. The edges

of the loading plate will be parallel to the longitudinal axis of the

bridge.

-

On the day of the competition, the judges will decide which one of the

three loading locations will be used; ir will be the same for all

bridges.

4. Testing

-

On the day of the contest, contestants will center their bridge on the

loading surfaces. They will have previously located the loading plate and

3/8 inch eye bolt to the selected loading position.

-

The load will be applied from below, as described in section

3 above.

Competition loading will stop at 50. kg. However,

loading will continue until bridge failure (see 4d).

-

Bridge failure is defined as the inability of the bridge to carry

additional load, or a load deflection of 25.4 mm under the loading

location, whichever occurs first.

-

The bridge with the highest structural efficiency, E, will be

declared the winner. Bridges failing above 50. kg will be considered

to have held 50. kg for efficiency calculation.

E = Load supported in grams (50,000g maximum) / Mass of bridge in grams

5. Qualification

-

All construction and material requirements will be checked prior to

testing. Bridges failing to meet these requirements will be

disqualified. Bridges disqualified prior to the start of the contest

may be tested as exhibition bridges at the discretion of the builder

and the contest directors.

-

If, during testing, a condition becomes apparent (i.e., use of

ineligible materials, inability to support the loading plate, bridge

optimized for a single loading point, etc.) which is a violation of

the rules or prevents testing as described above in Section 4, that bridge shall be disqualified. If the

disqualified bridge can accommodate loading, it may still be tested as

an exhibition bridge as stated above.

-

Decisions of the judges are final; these rules may be revised as

experience shows the need. (Please check our web site,

http://bridgecontest.phys.iit.edu after January 7, 2011, to learn whether

any changes have been made.)

Last update: February 4, 2011

[ Bridge Contest Home ] [ International Contest ] [ Chicago Regional Contest ]

[ Region Locator ] [ Official Documentation ] [ Other Bridge Links ]

For further information, contact: Prof. Carlo Segre -

segre@illinoistech.edu,

Illinois Institute of Technology

© International Bridge Building Committee, 2024